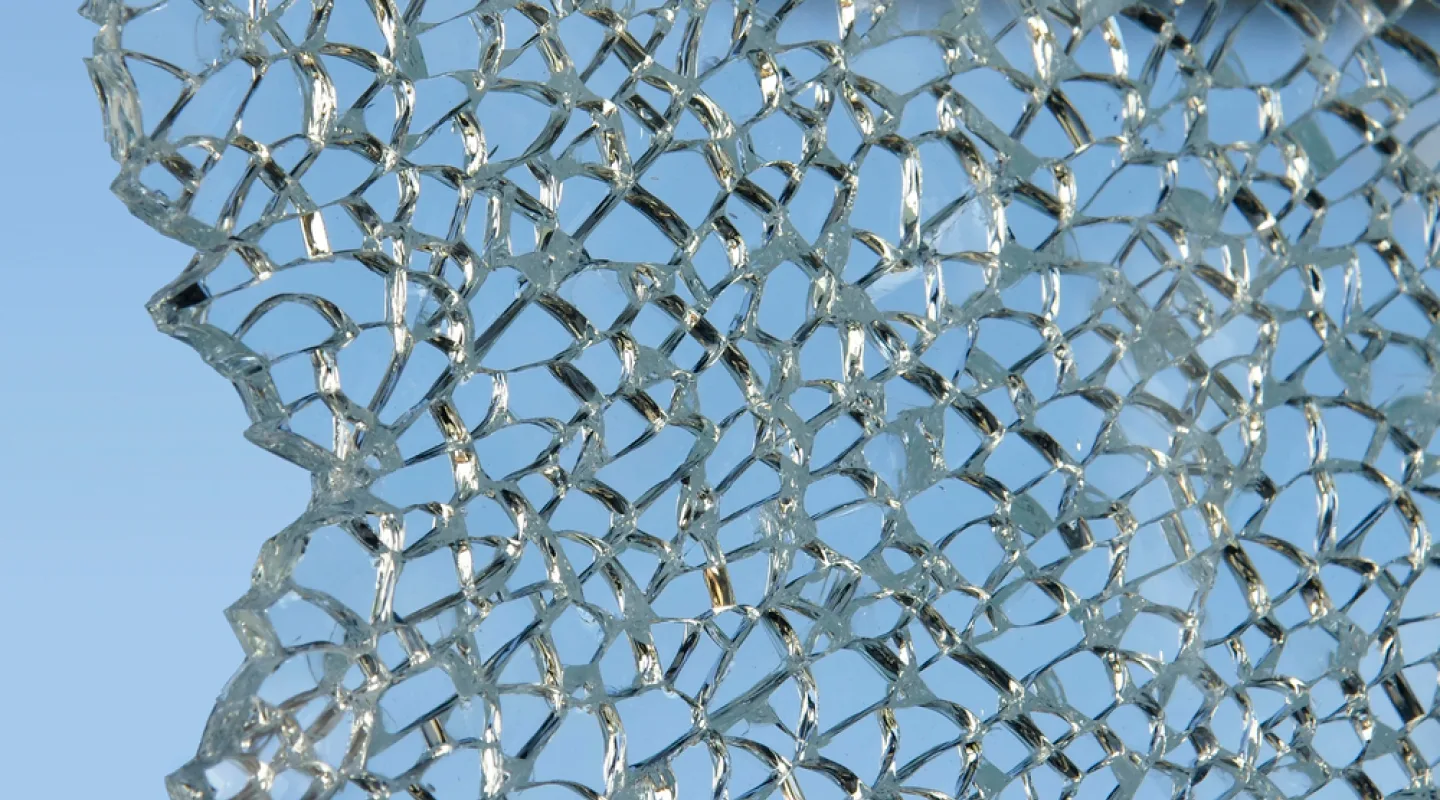

Made from common annealed glass through a process called thermal tempering, Tempered glass is among the two varieties of safety glass used in applications that require standard glass to pose a potential danger. Tempered glass does not crack into sharp shards, as it is 4 to 5 times stronger than the standard glass. The brittle nature of custom tempered glass causes it to shatter into small oval-shaped pebbles when broken. This eliminates the danger of sharp edges. Due to this property, along with its strength, tempered glass is often referred to as safety glass. Process Involved Tempered glass is made using a process called Thermal Tempering that involved extreme heating followed by rapid cooling. In thermal tempering process, the tempered glass Brooklyn is exposed to extreme heat until it softens and then, it is rapidly cooled. This makes glass harder and stronger than the normal glass and an annealed glass of the same thickness.

A fully tempered glass is considered a safety glass that crumbles into little blunt pieces on breaking. This nature of glass minimizes the risk of injury to great extent. A Tempered Glass manhattan is in great demand for its use in modern glass façade, in which the strength of the glass is of great significance. Besides, such a strong glass is recommended to be used in windows positioned on skylights or high floors where people have to stand on the top for cleaning it. The areas that are subjected to the high risk of impact breakage or thermal breakage require fully tempered glass with a view to avoiding any chances of injury. Other recommended use of Tempered Glass nyc with great strength include patch fittings, bolted fittings and point fixed glazing. Pros It is evident that the tempered glass is widely used across the world because of its strength. But, this quality of tempered glass brings in many other benefits that are listed below.

- Safety: As and when tempered fully tempered glass breaks irrespective of the impact, it immediately disintegrates into small pieces of blunt shape. This nature of tempered glass reduces the probability of any serious cutting or sharp injuries in contrast to normal annealed glass.

- Strength: Tempered Glass manhattan is generally stronger than the annealed glass and twice the heat-strengthened glass of same thickness, size or type and that’s the very reason for its use in ASTM C 1048. The minimum surface required for compression in fully tempered glass is 10000 psi and the same surface required for a heat-strengthened glass is 4000-7000 psi.

- Thermal Breakage: The general tendency of glass surface to heat up when direct sunlight falls on its pane is not applicable with custom tempered glass. This heating in tempered glass is not consistent in nature. While the central part is exposed to sunlight and thus, heats up faster, the edges are comparatively cooler. This nature of tempered glass creates a difference in temperature even when the same glass pane is used.

- Edge Strength: A fully tempered glass features high edge strength contrary to normal annealed glass and this gives designers autonomy to use in point fixed glazing or spider glazing.